Reusable Silicone N95 Alternative: A Game-Changer in Healthcare PPE

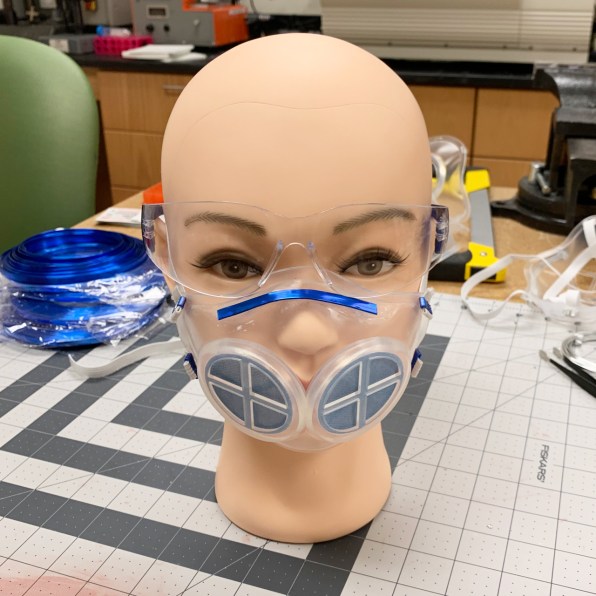

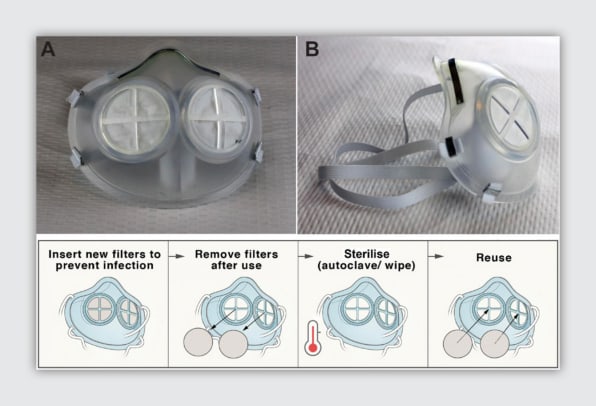

As COVID-19 continues to challenge healthcare systems across the U.S., a reusable silicone N95 alternative is emerging as a sustainable, cost-effective solution to critical mask shortages. Unlike traditional N95 masks designed for single use, this new mask can be sterilized multiple ways and reused—helping protect frontline workers while reducing waste.

Why a Reusable Silicone N95 Alternative Matters

Florida alone has reported over 12 times more cases than the entire country of Australia. Amid such spikes, healthcare providers continue facing PPE shortages—especially N95 masks. Hospitals have been forced to reuse disposable masks, creating safety concerns. While stopgap measures like disinfection protocols are in place, researchers at MIT and Brigham and Women’s Hospital have developed an innovative reusable silicone mask that could solve the problem.

“When the virus started popping up in the U.S., we talked about the need for PPE and quickly realized there would be a massive shortage—not just here, but globally,” says Dr. James Byrne, a radiation oncologist and MIT research affiliate. “That’s how we created a reusable, scalable, flexible, and conformable mask that could meet long-term PPE needs.”

Built to Last: The Power of Silicone

The team chose silicone rubber for its durability and flexibility. Already used in medical-grade equipment and even baking tools, silicone withstands high heat and chemical sterilization. Researchers tested sterilizing the mask with ovens, steam, bleach, and rubbing alcohol—and none damaged the material.

“We wanted to have a system that could be accessible and used by anyone globally,” says Giovanni Traverso, MIT mechanical engineering professor and gastroenterologist at Brigham and Women’s Hospital.

Scalable, Comfortable, and Easy to Use

Another big advantage? Scalability. Silicone can be injection molded, a standard industry process, making it possible to produce these masks in large quantities. That’s essential when supplying hospitals, clinics, and essential workers.

The design also improves comfort and usability:

-

It flexes to fit different face shapes

-

A quarter of test participants preferred it over traditional N95s

-

Its clear body allows easier communication with patients

Two small, removable N95 filter inserts fit into breathing ports. These disposable inserts use less material than full masks, accelerating production and reducing waste. Researchers are also exploring reusable filters for added sustainability.

FDA Approval and Market Rollout

In tests with 20 healthcare professionals, the masks fit securely and comfortably. Based on feedback, the team has made minor design tweaks—like shifting filter positions so facial expressions are more visible to patients.

They’re currently running environmental impact and cost-effectiveness studies, showing promising results:

-

Estimated unit cost: $15

-

Reusable up to 100 times

-

Cost per use: less than $0.25

-

Filter inserts: under $1 each

“There is a potential significant savings compared to the standard disposable system,” says Traverso.

The team is now setting up a company to bring the product to market and seeking FDA emergency use authorization for both healthcare providers and the general public.

Conclusion

This reusable silicone N95 alternative could mark a turning point in how we approach PPE in healthcare. By combining sustainability, cost savings, and user comfort, it offers a smarter, safer solution for today’s global challenges.

🔗 Learn more from MIT’s official report on the silicone mask development.

📘 Related: How Dental Practices Adapted to PPE Challenges During COVID